Computational models of perfusion flow through scaffolds

For tissue-structured cultivated meat production, the transition from the proliferation phase to differentiation phase may involve seeding cells onto a prefabricated scaffold within a perfusion bioreactor. Medium is then perfused through the cell-laden scaffold, providing nutrients and oxygen as cells differentiate and mature. Computational models are needed to describe fluid flow through scaffolds to better understand mass transfer and shear forces. These models will inform considerations for scaffold materials, geometries, dimensions, fabrication methods, and bioprocess design as well as considerations for the composition and viscosity of the medium.

-

Cultivated

- Research

- R&D

- Bioprocess design

- Scaffolding

- Academics

- Startups

Current challenge

When perfusing fluid through a porous structure, flow will generally obey Darcy’s Law of permeability, which describes the relationship between pressure, length of flow, and the liquid’s velocity. To maintain a given rate of flow through a dense scaffold, higher pressures may be needed, resulting in shear stress that is intolerable to cells within the scaffold. Shear stress from fluid flow through a scaffold of just several millimeters in thickness can influence traits such as proliferation, differentiation, and extracellular matrix deposition. Additionally, filling of void space within the scaffold due to cell proliferation may result in dynamic shifts in fluid flow and shear forces that may need to be controlled to ensure uniform nutrient access and cell viability. The number of parameters at play in these environments makes the optimization of scaffold designs, media formulations, and bioprocess variables especially challenging for thick tissues.

Proposed solution

Computational modeling can drastically reduce the amount of empirical experimentation that must be done to develop a deep enough understanding of a system to generate predictions for rational optimization. To accelerate R&D pertaining to cultivating thick tissues, computational fluid dynamic models using a variety of potential scaffold biomaterials, porosities, geometries, and parameters such as void space filling and medium viscosity is needed to better understand and predict the shear stress and fluid flow rates that cells may be subjected to within a scaffold. These models can inform the rational design of scaffolds and media optimization and, in turn, methods for scaffold fabrication and cell integration.

Combining these models with empirical experiments using different cell types can assist in understanding the effects of scaffold and bioprocess design on key aspects like cell proliferation, differentiation, maturation, and extracellular matrix deposition. Additionally, local microenvironments created as cells progressively occupy void space within scaffolds may necessitate the creation of sensor systems to dynamically adjust flow rates; computational models can inform such adaptive control systems.

Anticipated impact

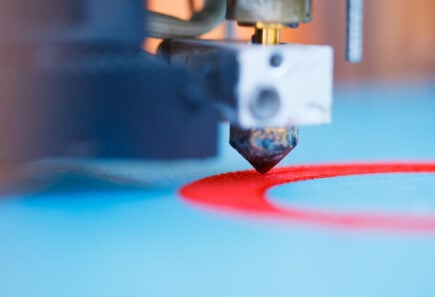

Computational modeling can drastically reduce demand on scarce experimental resources by reducing the number of experiments required to optimize process variables. Computational models may fundamentally influence how the manufacturing of intact cultivated meat products is conducted. For instance, if a scaffold is designed to be embedded within a large-volume bioreactor, its maximum size may be limited due to shear stress or nutrient mass transfer limitations. This could influence the overall differentiation strategy, potentially favoring alternative bioreactor systems or scaffold designs that rely more heavily on innovative approaches like additive manufacturing technologies or in situ scaffold fabrication. Alternatively, modeling may suggest that large scaffolds can effectively be used that would accelerate the development of large perfusion bioreactors with embedded scaffolding that are currently of limited availability.

Related efforts

- Computational models in perfusion systems with scaffolds have been developed for the study of several tissues in regenerative medicine, including considerations for leveraging biophysical fluid forces exerted on cells to aid differentiation.

- The Cultivated Meat Modeling Consortium is a group of computational modelers and scientists with interest in modeling cell behavior on scaffolds. See their first white paper.

GFI resources

Deep dive: Cultivated meat bioprocess design

Learn about the bioprocess design parameters critical to the development of cultivated meat.

Deep dive: Cultivated meat scaffolding

Learn about scaffolding materials and methods for cultivated meat.

Find collaborators

Join the GFIdeas global community of 2,000+ entrepreneurs, scientists, investors, and subject matter experts. Discuss projects on the members-only Slack community, attend monthly seminars, and use the community directory to help you find collaborators working on similar Solutions!

Related solutions

-

Cultivated

3D microenvironments for cell expansion

Proliferation and high-density cell growth are fundamentally important to scaling cultivated meat production. Recent demonstrations of stem cell expansion in 3D microenvironments such as encapsulated spheres or tubules can generate…

-

Cultivated

Establishment of cell line repositories and standardized isolation protocols

Development of humanely-sourced and thoroughly documented and characterized cell lines from a variety of common food species—together with a mechanism for licensing and distributing these lines to researchers and companies—will…

-

Cultivated

Species-specific genomic studies enabling assay development for regulatory standards and cell line optimization

A suite of assays and genomic knowledge exists for humans and commonly used laboratory species such as mice or fruit flies. However, the same species-specific infrastructure does not exist equally…

Explore the full solutions database

Browse 300+ startup ideas, commercial opportunities, research projects, and investment priorities throughout the alternative protein supply chain.

Related GFI research grants

3-D printing bioinks

Learn about GFI grantee Dr. Sara Oliveira’s work 3D bioprinting scaffolds for cultivated meat the International Iberian Nanotechnology Laboratory in Portugal.

Plant-based scaffolds

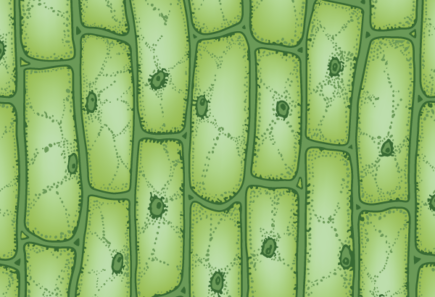

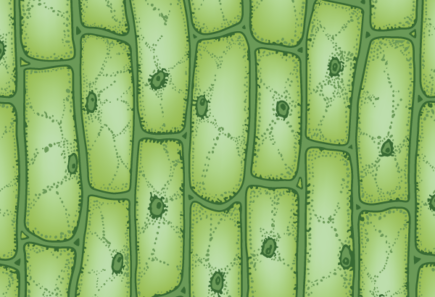

GFI is building plant-based tissue scaffolds for cultivated meat with Dr. Masatoshi Suzuki at University of Wisconsin, Madison

GFI’s 2021 Competitive Research Grant RFP catalyzes science of whole-cut alt protein products

GFI’s 2021 Competitive Research Grant RFP is designed to catalyze whole-cut alt protein meat products—a critical step on the journey toward a safe and sustainable global food system.

Machine learning for fish growth media

Learn about Dr. Reza Ovissipour’s research using machine learning to optimize growth media for fish cells at Virginia Tech.

Get involved

If you’d like to fund a research project, work on any of these solutions, share information about related efforts that are already underway, or elevate new ideas for advancing the alternative protein industry, we’d love to hear from you!